The development process

Proposed solution

Early in the development process, we can help you develop solution proposals based on the needs the product should fulfill. We are a discussion partner regarding design, material selection, manufacturing method, and possible rationalizations. We map out your needs and ideas to jointly develop a development process that ends in a product, adapted both for the market and efficient production.

Prototype development

After reviewing your drawings, we provide feedback with suggestions on materials, manufacturing methods, and product solutions. Together, we decide on the desired appearance. In our prototype room, we then produce anywhere from a few to thousands of prototypes for testing. After several rounds of product critique, we refine the intended production process, find the right cost level, and are ready to start volume manufacturing.

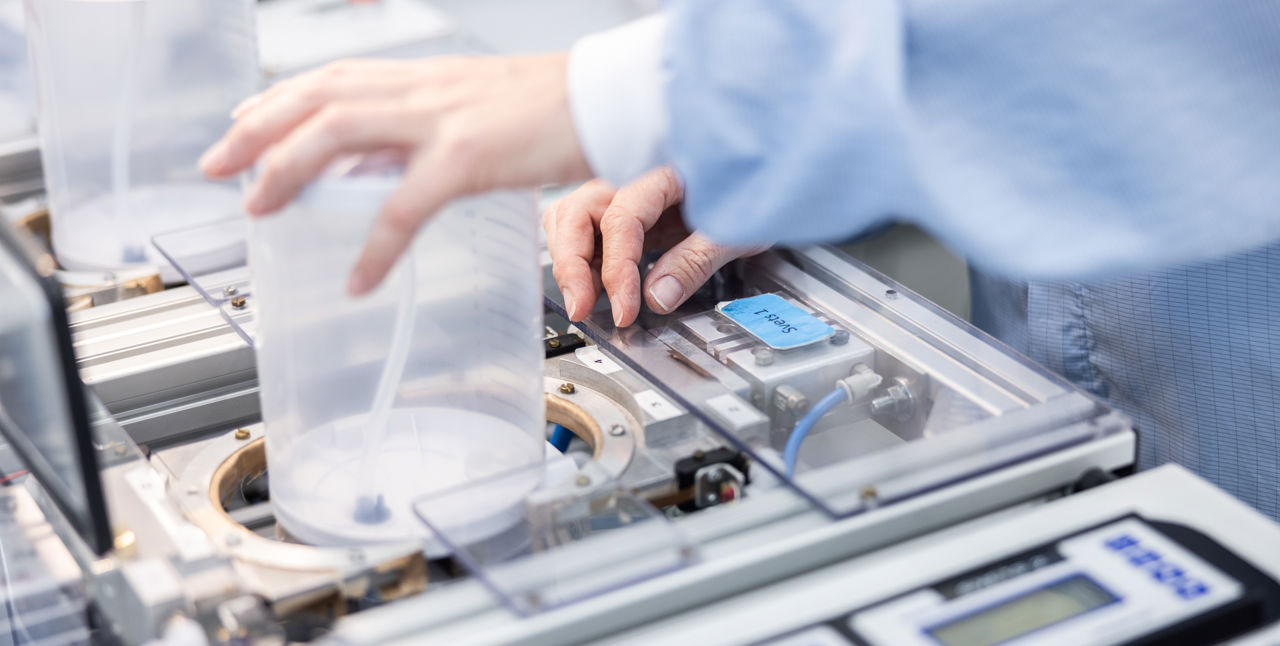

Volume manufacturing

Together, we decide whether to use our existing production capacity or invest in new production equipment for you. Based on that, we set up series production for you in our cleanroom facility in Gislaved. We coordinate work with producers of the components such as injection-molded parts, hoses, and the foil material itself. This ensures the highest quality of the final product.

Post-processing & assembly

In addition to welding, we perform post-processing and applications that refine the product to the desired level. This can include stamping, assembling external components, printing, liquid filling, and packaging. Based on your agreements, we can also purchase products and components to assemble them into the desired finished product. This happens naturally as we are often the last production stage before final delivery.

Testing & validation

Together with the client, we determine the requirements for each product and based on this, decide how quality control should be conducted. We can test 100% of all products we produce for you through vision systems to guarantee zero defects. Throughout the production process, validations and documentation are carried out according to your wishes. Each product is provided with a batch protocol for complete traceability.

Product development over time

Our clients often have projects that run for several years. It is our responsibility as a supplier to drive a long-term product development process. As volumes increase, production must be rationalized to ensure the final product maintains the right price. It can also involve developing new materials that allow us to achieve even better product properties. We are experts in plastic welding, foils, and their properties, and we are always looking for improvement opportunities. Combined with our in-house development department and many years of cleanroom production experience, we can offer you many years of collaborative development.